How to seal kraft paper bags?

Sealing kraft paper bags is essential, particularly for businesses that rely on packaging and delivering products. Whether you’re in the food industry, eCommerce or retail, a well-sealed bag ensures the integrity and quality of the items inside, while it might seem like a daunting process, it’s quite easy!

In this blog post, we’ll take an in-depth look at which type of sealing kraft paper bags requires, provide useful tips on achieving the best possible results when using them with any product type and outline some of the great benefits of opting for these versatile bags over others on the market today.

Process To Seal Kraft Paper Bags

Materials needed for sealing kraft paper bags

You’ll need specific materials and tools to seal kraft paper bags efficiently and securely. Importantly, the exact tools may vary depending on your preferred sealing method.

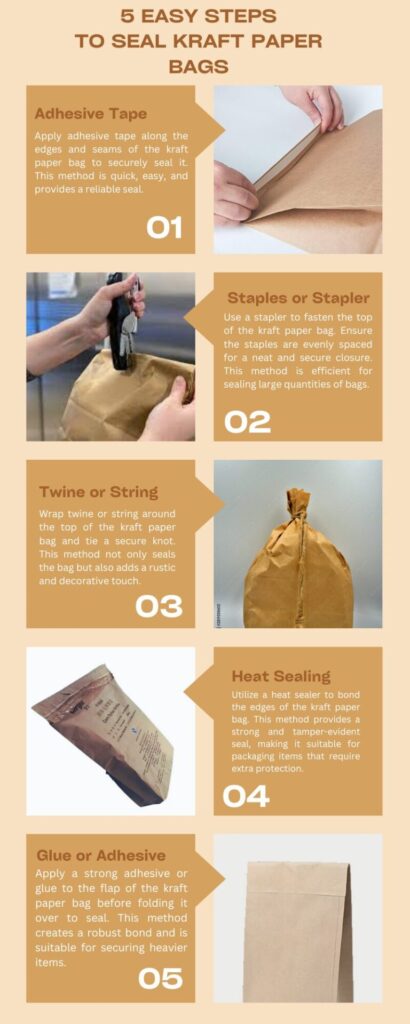

- Heat sealer: Heat sealer is a device that melts the opening of the bag together, forming a tight seal. This method is most appropriate for businesses that need to seal a large number of bags quickly.

- Adhesive tape or stickers: For a less permanent seal, adhesive tape or custom stickers can be used. This is an excellent option for businesses that want their customers to be able to reseal the bag.

- Twist ties or ribbons: If you are going for a more aesthetic appeal, consider using twist ties or ribbons. These not only seal the bag but also add a decorative touch.

- Stapler: A heavy-duty stapler can also be used for sealing kraft paper bags, particularly for larger and heavier items.

- Labels: If you’re using a heat sealer, labels can be applied after sealing, for branding or for providing product information.

Remember, the sealing process you choose should not only depend on efficiency but also on the nature of your product and the presentation you want to achieve.

Steps Of Sealing Kraft Paper Bags

- Prepare the bag: Start by filling the kraft paper bag with the product. Ensure that it’s not overfilled so that there is enough room at the top of the bag for the seal.

- Choose your sealing method: Next, choose your preferred sealing method based on your specific needs and the materials available. This could be a heat sealer, adhesive tape, a stapler, twist ties or ribbons.

- Apply the seal: If you’re using a heat sealer, place the open end of the bag in the sealer and press down until the bag is sealed. If using adhesive tape or stickers, apply them over the opening of the bag to seal it. For staplers, simply staple the top of the bag closed. If using twist ties or ribbons, gather the top of the bag and wrap the tie or ribbon around it, then secure it with a knot or bow.

- Check the seal: After applying the seal, make sure to check that it is secure and that there are no gaps where the product could spill out. A good seal should keep the product inside the bag and prevent any external contaminants from entering.

- Add labels or decorations: Finally, add any labels or decorations to the sealed bag. This can include branding, product information or other details. With the bag sealed and labeled, it’s now ready for delivery or display.

Tips & Tricks For Perfect Bag Seal

- Choose the right sealer: Right sealer depends on the size of the bags, the weight of the contents and the scale of the operation. Choose a sealer that suits your needs.

- Don’t overfill bags: Overfilling bags can make them harder to seal and more likely to break. Always ensure there’s enough space at the top for a secure seal.

- Ensure your tools are in good condition: Whether you’re using a heat sealer or a stapler, ensure your tools are in good condition. Damaged tools can lead to poor seals.

- Choose the right adhesive: If you’re using adhesive tape or stickers, make sure they are strong enough to hold the weight of the contents.

- Check the seal: Always check the seal after sealing the bag. A good seal should be secure and without any gaps.

- Use labels for added security: Labels can help secure the seal further and provide an opportunity for branding and providing important product information.

- Consider the presentation: Sealing method you choose can also add to the overall presentation of the bag. Consider using twist ties or ribbons for a more aesthetic appeal.

Common mistakes in sealing kraft paper bags and how to avoid them?

- Neglecting to check the seal: Often, people seal the bag and move on to the next one without ensuring the seal is secure. Always check each bag post-sealing to avoid any spillage or contamination.

- Using the wrong sealing method: Not all sealing methods suit all types of products or bags. For instance, delicate items might not cope well with heat sealing. Understand the product, the bag and the most suitable sealing method to prevent any damage.

- Overfilling the bags: Overfilled bag is prone to tear and harder to seal. Always leave adequate space at the top for the seal.

- Not maintaining the sealing tools: Regular maintenance of your tools, especially heat sealers, is vital for their efficient operation. A malfunctioning tool can lead to improper sealing.

- Improper labeling: Labels not only provide product information but also add to the bag’s visual appeal. Improper or misaligned labels can give a wrong impression about your brand. Always ensure labeling is done correctly and neatly.

- Not considering aesthetics: While the primary purpose of sealing is to secure the contents, the appearance of the bag is also important. Aesthetically pleasing packages, such as those sealed with ribbons or twist ties, can enhance the customer’s unboxing experience. Don’t overlook the visual aspect while sealing the bags.

FAQs – Kraft Bags Sealing Method

What is the best method to seal kraft paper bags?

There isn’t a one-size-fits-all answer to this question, as the best sealing method depends on the size of the bags, the weight of the contents and the scale of your operation.

Consider using a heat sealer for larger operations, while adhesive tapes or stickers might be more suitable for smaller-scale businesses.

Can I use any type of adhesive tape or sticker to seal kraft paper bags?

The type of adhesive tape or sticker you use should be strong enough to secure the bag and hold the weight of the contents.

Not all tapes or stickers provide the same level of adhesion, so choose a product that suits your needs.

How can I ensure a secure seal on my kraft paper bags?

Always leave enough room at the top of the bag when filling it to allow for a secure seal. Additionally, ensure your sealing tools are in good condition and always check the seal after sealing the bag. Labels can also provide added security.

What should I do if my heat sealer isn’t making a secure seal?

If your heat sealer isn’t functioning properly, it might need maintenance or repair. It’s important to keep your tools in good condition to ensure a secure seal. Always check the manufacturer’s instructions for troubleshooting and maintenance tips.

Wrap Up

Sealing kraft paper bags is an essential task that requires careful attention to the product, the bag and the sealing method. The goal is to ensure the product’s safety and enhance the customer’s unboxing experience.

Choosing the right sealing method, maintaining your tools, correct labeling and not overlooking aesthetics are some of the critical areas to focus on.

While efficiency in sealing is important, it should not compromise the presentation or the security of the product inside. Therefore, understanding the nuances of each sealing method and selecting the one that best fits your needs can make a significant difference in the final outcome.

Remember, the way you package and present your product is a reflection of your brand and can impact the customer’s perception and their overall experience with your business.